Contact us

Phone: +86-17773116205

WhatsApp: +8617773116205

No.61 Lufeng Rd,Yuelu District, Changsha, Hunan Province, China. 410013

Alloy Roller Shell/ Alloy roller ring

- 产品描述

-

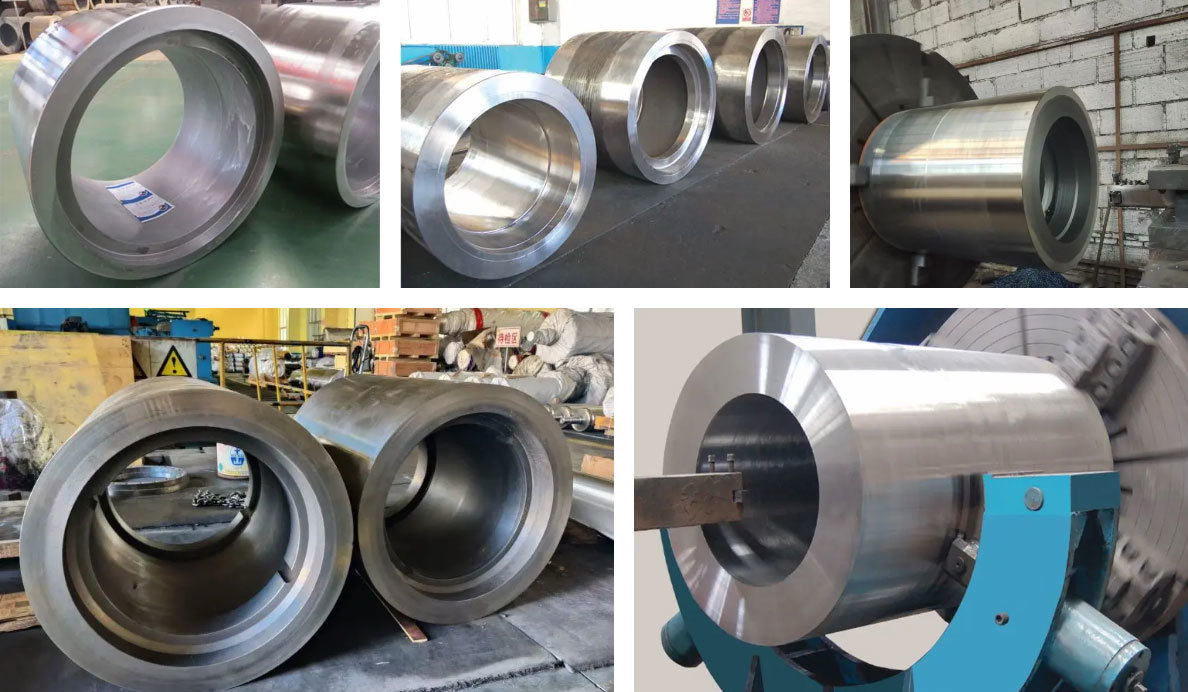

Alloy Roller Shell/ Alloy roller ring

Roll shells for various machines are one of our company's main products. The outer surface of the roller body is made of high-quality nickel chromium molybdenum alloy, melted in an electric furnace, and cast using a composite centrifugal casting process, which is finely processed. The surface of sleeve rollers has the characteristics of high hardness, good wear resistance, and durability, which are best-selling in China and exported to more than 30 countries and regions, winning the recognition of our customers.

Roller shells are cylindrical components of Double-roller machine, four-roller crusher, roller press machine, which is suitable for brick, metallurgical machinery, ceramics, metallurgy, refractory materials, artificial sand making and other industries.

Key benefits of alloy steels are higher strength, hardness, wear resistance, and toughness compared to plain carbon steel roller shells. This allows them to withstand heavy loads and use in high impact environments.

Typical applications include rollers used in steel mills, mining conveyors, crushers, rotary kilns, and large construction equipment. The alloy shells provide durability in harsh operating environments.

Advantages

1. This series of products have the characteristics of ultra-high wear resistance and deep working layer, which can replace and excel the imported products of the same kind, and the technology has reached the international leading level.

2. The high alloy material of this product can be divided into several categories according to the hardness of crushed materials. The material of high alloy cast iron in working layer is different, and the price is also different. Customers can customize it according to their own working conditions.

3. Under the condition of relatively uniform material distribution, equipped with grinding equipment and basically able to handle, install and use correctly, the service life of most rollers averages more than 2-3 years.

4. Our company produces centrifugal bimetal compound rollers with high hardness, good wear resistance, high strength and toughness, safe use and obvious cost-effective advantages.

5. Centrifugal whole high chromium alloy roller rings are used in ultra-fine roller pairs under 1.0mm in Europe, with service life of more than two years.

6. The 1400 * 1200 rollers is the largest size product in the industry and reaches the highest level of technology in the domestic industry.

Main Technical Parameter

Diameter of Roll Body Length of Roll Surface Hardness of Roll Body Thickness of Alloy Layer 200-1200mm 200-1500mm HS66-78 10-55mm Product photos

Product Package

Our Company

With more than 30 years' history, Changsha TangChui Rolls Co., Ltd is a large and professional enterprise in China that integrates research, development and manufacture of alloy rolls into one. The company owns advanced middle frequency furnace, compound centrifugal casting machine, precise and complete metal cutting equipment and advanced and modern quality measurement and control means. The alloy rolls we manufactured have the characteristic of high rigidity, high intensity, good wear resistance, anti crack and anti strip, sell well within the country, have been exported to a couple of countries covering Asia, Africa and Europe, and win good reputations from our customers.

Contact Us

Keywords: