Contact us

Phone: +86-17773116205

WhatsApp: +8617773116205

No.61 Lufeng Rd,Yuelu District, Changsha, Hunan Province, China. 410013

Flour mill grinding rollers

- 产品描述

-

Product Introduction

Flour mill rollers are used to grind wheat and other grains into flour in flour mills. Grinding rollers are the main components in flour mills. The quality of the grinding roller is directly influence the quality of Flour, cost and economic benefits. So you must choose high quality grinding rollers as long as you use.

With a history of more than 20 years, the roller for flour mill is the key product of our factory. The body of the grinding roller is manufactured with quality alloy, such as high nickel, chromium, molybdenum and high quality pig iron smelted in electrical furnace and founded by composite centrifugal casting technology.

High-quality carbon structural steel is adopted quenching and tempering is done to ensure steady turning of the grinding roll and low noise.

Grinding rolls of our company are of complete models and high quality, which have exported in India, Africa, Europe and have gained good reputation from our customers and partners.

We can also produce all kinds of grinding rolls with special specification according to customers requirement.

Advantages

RAW MATERIAL :

From IRON&STEEL GROUP,CO.LTD among the top 100 Chinese enterprises.ALLOY LAYER:

1. Thickness of alloy layer 25mm+, which is thicker than most factories, Thus can make sure of the hardness of roller better than other's.

2. Technology and material of alloy. Roller body is made of high quality nickel –Chromium-Molybdenum alloy by compound centrifugal casting plus electric furnace smelting technology, make sure our rolls of high hardness, homogenization and wear property.TESTING SYSTEM:

1. Dynamic balance tests are done to guarantee the accuracy of stable running of rolls.

2. From row material to finished product, more than 20 steps, each step with times of strict tests to make sure high quality of our rolls.PRICE:

1. Competitive price with better quality, longtime service of our rolls, more profitable to our customers.CUSTOMERS SAY:

1. The price is cheaper but quality is better than Turkey'sMain technical parameters of the grinding roller

Hardness of

roll body(H.S.)Hardness of

sand roll(H.S.)Hardness of

Head Axis(H.B)Thickness of

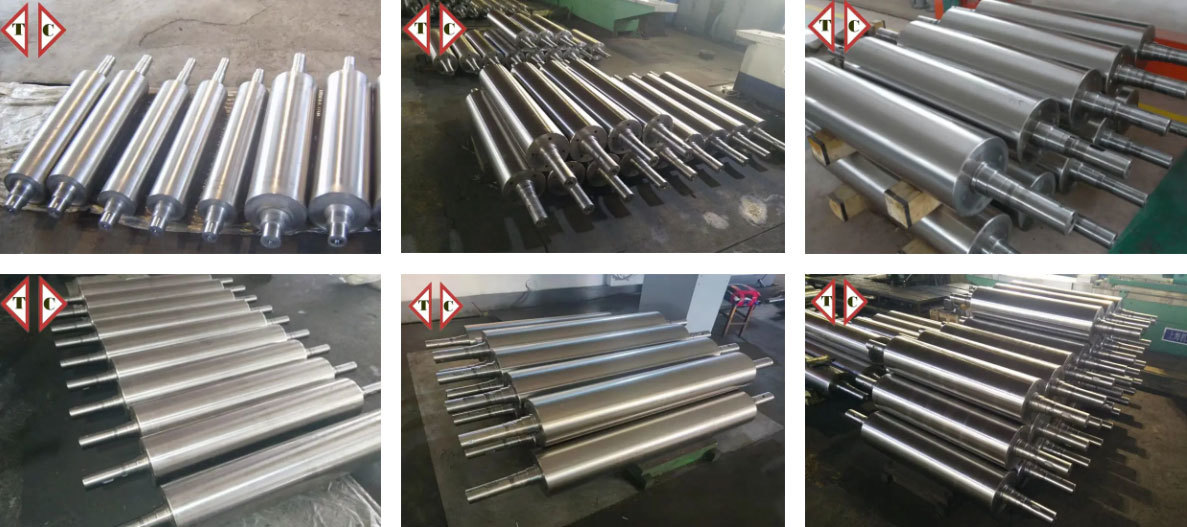

alloy layer(mm)73±2 63±2 220-260 20-25 Product photos

Product Package

Our Company

With more than 30 years' history, Changsha TangChui Rolls Co., Ltd is a large and professional enterprise in China that integrates research, development and manufacture of alloy rolls into one. The company owns advanced middle frequency furnace, compound centrifugal casting machine, precise and complete metal cutting equipment and advanced and modern quality measurement and control means. The alloy rolls we manufactured have the characteristic of high rigidity, high intensity, good wear resistance, anti crack and anti strip, sell well within the country, have been exported to a couple of countries covering Asia, Africa and Europe, and win good reputations from our customers.

Contact Us

Keywords: