Contact us

Phone: +86-17773116205

WhatsApp: +8617773116205

No.61 Lufeng Rd,Yuelu District, Changsha, Hunan Province, China. 410013

Calendar rolls

- 产品描述

-

Calendar rolls

Calendar Roll is a key component in the paper, textile, and plastic film industries, used to improve the surface characteristics of materials through a process called calendering. Below is a detailed introduction to its applications in paper and textile production.

1. Calendar Roll in Paper Production. In the paper industry, the calendar roll is the core component of the calendering process, which improves the surface properties of paper through high temperature and pressure.

Types of Calendar Rolls for paper making:

Super Calender Rolls: Used for high-end paper production to achieve a smoother surface and higher gloss.

Coated Calender Rolls: These have a fiber or synthetic coating to adapt to different types of paper.

2. Calendar Roll in Textile Production. In the textile industry, calendar rolls are used to improve the appearance and feel of fabrics through a mechanical finishing process called calendering.

Types of Calendar Rolls for textile:

Friction Calender Rolls: These create a friction effect by running at different speeds.

Embossing Calender Rolls: These are used to imprint patterns on the fabric surface.

Advantages of our Calender Rolls

Improved smoothness and gloss of paper - The pressure applied by the rollers helps smooth out the paper surface and impart a glossy finish. The more rollers, the greater the calendering effect.

Flexibility: Rollers allow adjustments to nip pressure and temperature to optimize the calendering process for different paper weights/grades.

Durability and elasticity: Steel rollers maintain their shape and elasticity better compared to alternatives like felt belts. This ensures uniform pressure across the paper width.

Ease of operation and maintenance: Rollers are easy to install, replace and maintain compared to belt or plate calenders. No need for extensive lubrication or cooling systems.

Space saving: Roller stacks allow calendering in a relatively small footprint compared to the length needed for belt calenders.

Versatility: Small diameter rollers can be used for soft calendering without much gloss improvement. Larger rolls apply higher pressure for desired gloss levels.

Energy efficiency - The friction between rollers requires less energy compared to belts which need higher tensioning forces.

Main technical parameters

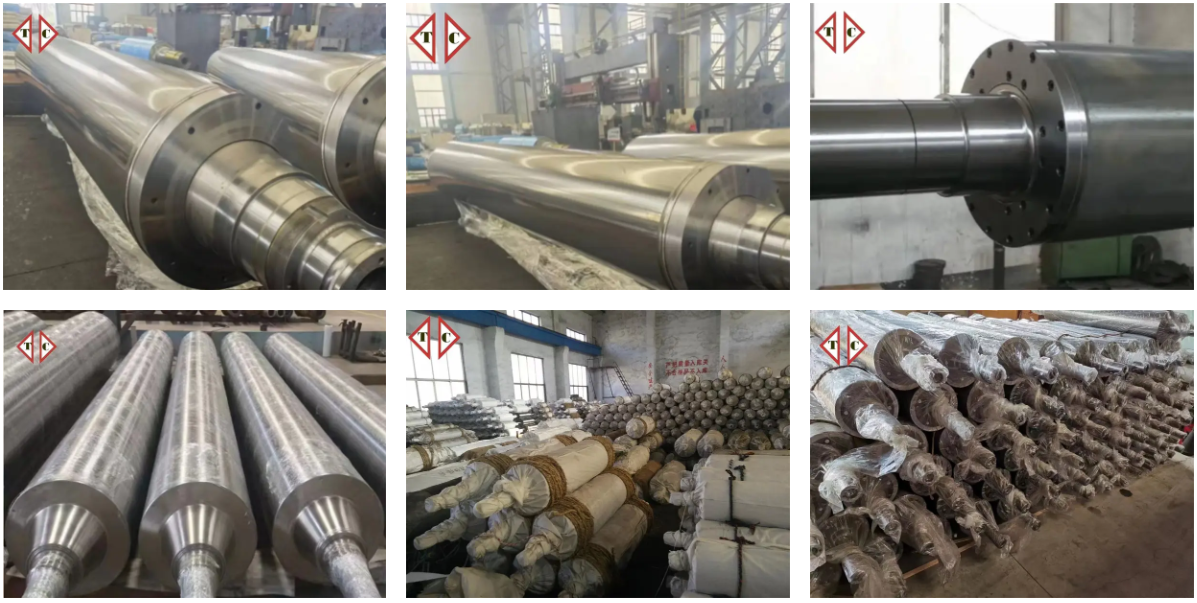

Main Technical Parameter Diameter of Roller Body Length of Roller Surface Hardness of Roller Body Thickness of Alloy Layer Φ200-Φ800mm L1000-3000mm HS75±2 15-30mm Product Photos

Our Company

With more than 30 years' history, Changsha TangChui Rolls Co., Ltd is a large and professional enterprise in China that integrates research, development and manufacture of alloy rolls into one. The company owns advanced middle frequency furnace, compound centrifugal casting machine, precise and complete metal cutting equipment and advanced and modern quality measurement and control means. The alloy rolls we manufactured have the characteristic of high rigidity, high intensity, good wear resistance, anti crack and anti strip, sell well within the country, have been exported to a couple of countries covering Asia, Africa and Europe, and win good reputations from our customers.

Contact Us

Keywords: